How the HoloLens can help build the buildings of tomorrow

By Asavin Wattanajan tra

tra

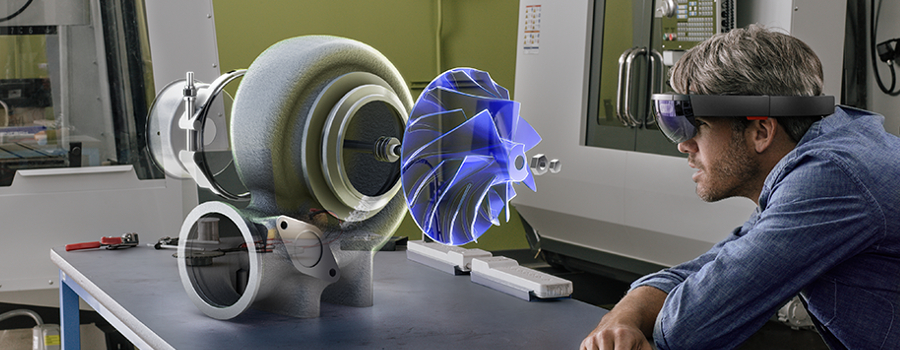

Engineers, architects and other experts in the construction industry are increasingly looking at the Microsoft HoloLens as a tool which can make their jobs easier and make them more effective.

A research centre looking at this is the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC), which sees the potential of the mixed-reality head mounted device that is capable to creating holograms. They are creating proof of concept applications for the hardware to automate assembly tasks and in-line support assistance.

The goal is that the HoloLens could be used for digitally assisted assembly techniques, helping engineers and technicians to improve quality and become more efficient by reducing rework, scrappage and concession.

The AMRC worked with the University of Strathclyde’s Advanced Forming Research Centre (AFRC) to create a demo for the HoloLens which showed off the possibilities of helping contractors visualise projects from its earliest stages.

The two research centres worked with Glasgow-based design visualisation firm Soluis Group and building designer and manufacturer Carbon Dynamic to create a prototype that uses the HoloLens to see a complete 3D rendering of the plumbing and wiring behind a plasterboard wall.

This system can be used to examine segments of a wall, ensuring there are no insulation gaps, before being sent to a construction site.

Other applications that the ARMC can demonstrate with the HoloLens include remote support and training, as well as a quick reference tool for complex machinery.

HoloLens as a construction tool

The technology demonstrates how engineering CAD data can be turned into full-scale, movable holograms and placed within a factory layout using the HoloLens’ environmental tracking. It showed that the HoloLens could have a massive role to play before, during and after construction of both domestic and commercial properties.

Prior to work commencing on site, those involved in a construction project will be able to accurately visualise and walk through a building before the foundations are even dug in – helping identify any potential issues before they occur.

It could also help during a build – contractors would be able to accurately see what’s behind walls and under floors. This could potentially lead to improved health and safety on sites as all guess work could be eliminated.

Post-construction it could also help with remedial and retrofitting work – even years down the line – as all of the information relating to a building, such as where electricity cables and pipe work is installed to the guarantees and instruction manuals for boilers, light fittings and showers, will be accessible using this technology.

David Grant, partnership development leader at the AFRC, said, “Projects like this can inspire hearts and minds in the construction sector to accelerate their adoption of new technologies – the potential for AR and VR in the industry is vast. Of course, this is just the first phase; demonstrating what could be achieved if the right platform was developed as a standard for the industry – the tools still need to be created.

“What we have done is prove that the technology works and, with the necessary skills, the right kind of software applications can be developed. While there are bespoke programmes already available, there isn’t a platform everyone can use to push and pull information from AR and VR devices. This is the first step forward in addressing that gap.”

Chris Freeman, AMRC Augmented Reality Technical Fellow, said, "The HoloLens could have benefits for inline process improvement.

“It could perform non-value added tasks from a manufacturing process and connect operators remotely to colleagues and supervisors, speeding up processes such as in-line verification; ultimately freeing up time and space on the workshop floor.”

Freeman said, “The AFRC was integral in laying the groundwork for the demonstrator, with thorough research and identifying the business drivers for introducing AR and VR capabilities. We’re hoping to do more in this area with our industrial partners, as more companies in the construction sector begin to realise the benefits these technologies can bring.”

The demo was a work instruction-based assembly application which was part of a full VR/AR/MR related toolset. The AMRC, supported by Microsoft, used the Universal Windows Platform to build the application, using standard back-end protocols to make the system architecture more viable.

Another example of a company creating HoloLens apps for the construction industry is Trimble, which created a HoloLens app for the Windows Store called SketchUp Viewer. This allows users to view and ‘inhabit’ designs in an natural and immersive way.

Want to learn more about Microsoft Mixed Reality? Check out the recent announcements and join us for free at Future Decoded to learn more from us and our partners!